Custom Designed Furniture: coffee table

I have a rule when it comes to decorating, and life, actually: never underestimate the details. And while, yes, sometimes the devil is in them, what you get as a result of careful, detailed effort is always worth it. So when it comes to my work, one of my most beloved projects is making custom furniture for my clients.

Although the process of creating these one-of-a-kind pieces can be quite complex, the final product is always worth it. So today I want to let you in on what it looks like to make one of these custom pieces--a behind-the-scenes look at a custom coffee table of mine in the works.

Creating a custom piece of furniture comes with an endless array of choices--from materials to sizes to finishes. But with those choices comes the beauty of knowing you are the only one who will have this exact piece. It’s your fingerprint on the room; your unique signature on your home.

I’ve spent years and years forging relationships with artisans all over the country who now play a role in carrying out my vision for these pieces; often with up to 3-5 people involved in making just one piece.

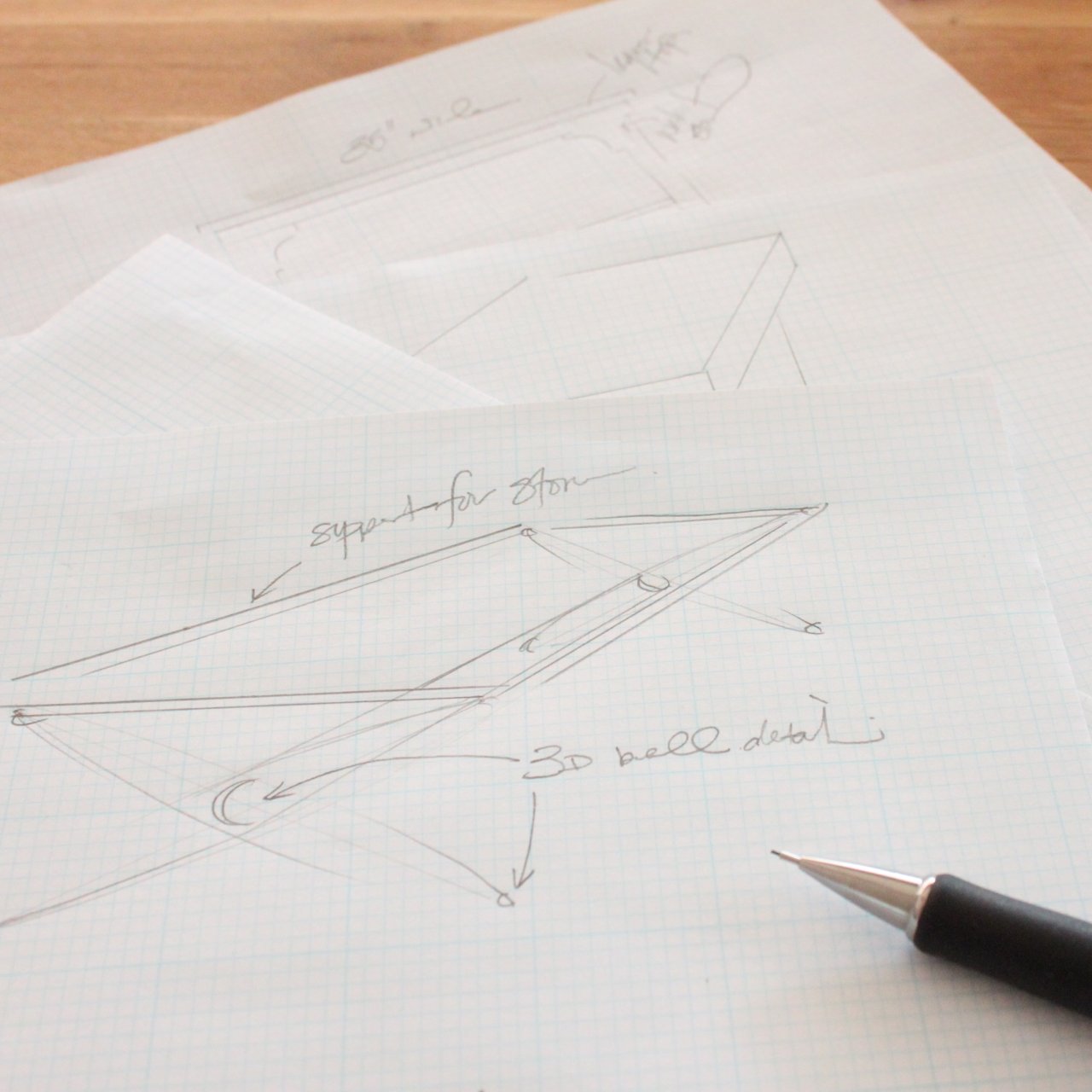

When I begin a passion project like this, it all starts with laying out the floor plan. I like to focus on key pieces that can become focal, conversational points in the room. Then comes the fun part: sketching. Call me old school, but I still love to sketch by hand. It’s an entirely unique process that I find helps me connect and think through the construction aspect of a design. How can I make this unique? What features should be different? Is this the best functionality? I’m also a big believer in the power of iterations to form an idea, so I will often work with over 20 ideas on paper before I identify the perfect design for my client.

This is the sketch of a coffee table I created recently for a client inspired by the floral wallpaper that sits right behind it. I took a modern interpretation of how the petals sit in relation to one another as the pattern for the base.

Once the drawing is approved by my client, it is rendered in CAD. This CAD rendering is then used to create the work order that the craftsmen can build from including details like dimensions, finish, timeframe, and transporting the piece.

Here is the CAD for the coffee table that allowed the iron worker to begin creating the table while I went to the stone yard in search of the right stone for the top of the coffee table. For this particular table, I went with a leathered limestone to compliment the weight of the iron base, with a simple, eased edge to create clean, transitional lines.

The iron base was recently finished and passed off to my decorative painter to undergo a burnished brass finish. From there, it was delivered to my studio to await its stone top application. And finally--in a most gratifying moment--it made its final voyage to my client’s newly built home.

Here is a quick snap shot of it in glory. Just you wait till the custom wool rug we are having made!

I must say, in the world of internet and who-can-make-it-for-less shopping, it does my soul well to work with real, passionate craftsman on quality pieces that will not only stand out in the crowd, but stand the test of time as well.

Want to keep the conversation going?

Join me on: Twitter- amymeierdesign | Instagram- amymeierdesign | Facebook